S275JR UNI EN 10025-2: A Comprehensive Guide

When it comes to selecting the right steel for your construction projects, understanding the specifications and standards is crucial. One such standard is the S275JR UNI EN 10025-2. This grade of steel is widely used in various industries due to its excellent mechanical properties and versatility. In this article, we will delve into the details of S275JR UNI EN 10025-2, exploring its composition, mechanical properties, applications, and more.

Composition of S275JR

S275JR is a structural steel grade that falls under the European standard UNI EN 10025-2. It is primarily composed of iron, carbon, and manganese. The carbon content in this grade ranges from 0.22% to 0.25%, while the manganese content is typically between 0.60% and 1.00%. The presence of these elements contributes to the steel’s strength, toughness, and weldability.

Mechanical Properties

The mechanical properties of S275JR make it an ideal choice for various construction applications. Here are some key properties:

| Property | Value |

|---|---|

| Minimum Yield Strength (MPa) | 275 |

| Ultimate Tensile Strength (MPa) | 410-550 |

| Elongation at Break (%) | 23 |

| Impact Resistance (J) | 27 at -20掳C |

These properties ensure that S275JR can withstand high loads and stresses, making it suitable for use in beams, columns, and other structural elements.

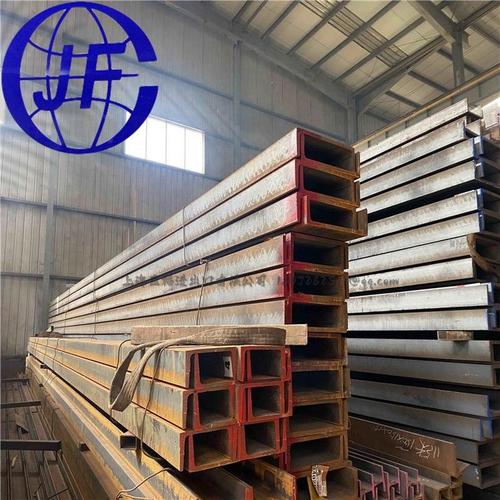

Applications of S275JR

S275JR is a versatile steel grade that finds applications in various industries. Some of the common uses include:

- Construction of buildings, bridges, and other civil engineering projects

- Manufacturing of machinery and equipment

- Production of automotive components

- Shipbuilding and offshore structures

Its excellent strength, toughness, and weldability make it an ideal choice for these applications.

Processing and Fabrication

Processing and fabrication of S275JR steel are relatively straightforward. It can be easily cut, shaped, and welded using standard techniques. Here are some common processing methods:

- Cutting: S275JR can be cut using various methods, such as sawing, shearing, and plasma cutting.

- Shaping: The steel can be shaped into various forms, such as angles, channels, and beams, using bending, rolling, and forging techniques.

- Welding: S275JR can be鐒婃帴 using various welding processes, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW).

These processing methods make it easy to incorporate S275JR into your construction projects.

Quality Assurance

Quality assurance is a critical aspect of the production and supply of S275JR steel. Manufacturers and suppliers must adhere to strict quality control measures to ensure that the steel meets the required specifications. Some of the key quality assurance measures include:

- Chemical analysis: Ensuring that the steel meets the specified carbon, manganese, and other element content requirements.

- Physical testing: Conducting tests to verify the mechanical properties of the steel, such as tensile strength, yield strength, and elongation.

- Non-destructive testing: Using methods like ultrasonic testing and magnetic particle inspection to detect any defects in the steel.

These measures help ensure that the S275JR steel you use in your projects is of high quality and meets the required standards.

Conclusion

S275JR UNI EN 10025-2 is a highly sought-after steel grade due to its excellent mechanical properties and versatility. Its wide range of applications, ease of processing, and adherence to strict quality control measures make